- Detects standstill using 2 impulse sensor(s)

- 2 safety contacts

- 2 Signalling outputs

Ordering data

| Note (Delivery capacity) | Phased-out product |

| Product type description | FWS 1205 B |

| Article number (order number) | 101170054 |

| EAN (European Article Number) | 4030661297163 |

| eCl@ss number, Version 9.0 | 27-37-18-19 |

| eCl@ss number, Version 11.0 | 27-37-18-19 |

| ETIM number, version 6.0 | EC001449 |

| Available until | 31.12.2021 |

Approval - Standards

| Certificates | BG cULus EAC |

General data

| Standards | IEC/EN 60204-1 BG-GS-ET-20 EN ISO 13849-1 |

| Climatic stress | EN 60068-2-3 BG-GS-ET-14 |

| Enclosure material | Glass-fibre reinforced thermoplastic, ventilated |

| Material of the contacts, electrical | Ag-Ni 10 and 0.2 µm gold-plated |

| Gross weight | 195 g |

General data - Features

| Stop-Category | 0 |

| Wire breakage detection | Yes |

| Automatic reset function | Yes |

| Reset after disconnection of supply voltage | Yes |

| Earth connection detection | Yes |

| Integral System Diagnostics, status | Yes |

| Number of LEDs | 1 |

| Number of undelayed semi-conductor outputs with signaling function | 2 |

| Number of safety contacts | 2 |

| Number of signalling outputs | 2 |

Safety appraisal

| Standards | IEC 61508 | |

| Performance level, up to | d | |

| Control category to EN13849 | 3 | |

| PFH-value | 1.00 x 10⁻⁷ /h | |

| 2 | |

| Mission Time | 20 Year(s) |

Mechanical data

| Mechanical life, minimum | 20,000,000 Operations |

| Mounting | Snaps onto standard DIN rail to EN 60715 |

Mechanical data - Connection technique

| Terminal Connector | Screw connection rigid or flexible |

| Terminal designations | IEC/EN 60947-1 |

| Cable section, minimum | 0.2 mm² |

| Cable section, maximum | 2.5 mm² |

| Tightening torque of Clips | 0.6 Nm |

Mechanical data - Dimensions

| Width | 22.5 mm |

| Height | 100 mm |

| Depth | 121 mm |

Ambient conditions

| Degree of protection of the enclosure | IP40 |

| Degree of protection of the mounting space | IP54 |

| Degree of protection of clips or terminals | IP20 |

| Ambient temperature, minimum | +0 °C |

| Ambient temperature, maximum | +55 °C |

| Storage and transport temperature, minimum | -25 °C |

| Storage and transport temperature, maximum | +70 °C |

| Resistance to vibrations to EN 60068-2-6 | 10 ... 55 Hz, Amplitude 0.35 mm |

| Restistance to shock | 30 g / 11 ms |

Ambient conditions - Insulation value

| Rated impulse withstand voltage Uimp | 4.8 kV |

| Overvoltage category | II |

| Degree of pollution to VDE 0110 | 3 |

Electrical data

| Thermal test current | 6 A |

| Rated operating voltage | 24 VDC ± 15 % |

| Rated AC voltage for controls, 50 Hz, minimum | 20.4 VAC |

| Rated control voltage at AC 50 Hz, maximum | 26.4 VAC |

| Rated AC voltage for controls, 60 Hz, minimum | 20.4 VAC |

| Rated control voltage at AC 60 Hz, maximum | 26.4 VAC |

| Rated AC voltage for controls at DC minimum | 20.4 VDC |

| Rated control voltage at DC, maximum | 28.8 VDC |

| Electrical power consumption, maximum | 5 W |

| Contact resistance, maximum | 0.1 Ω |

| Note (Contact resistance) | in new state |

Electrical data - Safe relay outputs

| Voltage, Utilisation category AC15 | 230 VAC |

| Current, Utilisation category AC-15 | 3 A |

| Voltage, Utilisation category DC13 | 24 VDC |

| Current, Utilisation category DC13 | 2 A |

| Switching capacity, minimum | 10 VDC |

| Switching capacity, minimum | 10 mA |

| Switching capacity, maximum | 250 VAC |

| Switching capacity, maximum | 8 A |

Electrical data - Digital inputs

| Input signal, HIGH Signal 1 | 10 … 30 VDC |

| Input signal, LOW Signal 0 | 0 … 2 VDC |

| Conduction resistance, maximum | 40 Ω |

Electrical data - Relay outputs (auxiliary contacts)

| Switching capacity, maximum | 24 VDC |

| Switching capacity, maximum | 2 A |

Electrical data - Electromagnetic compatibility (EMC)

| EMC rating | 10 V/m |

Integral system diagnosis (ISD)

| Note (ISD -Faults) | The following faults are registered by the safety monitoring modules and indicated by ISD. |

| Faults | Failure of the safety relay to pull-in or drop-out Fault on the input circuits or the relay control circuits of the safety monitoring module Failure of the proximity switches Failure of one channel being evaluated Interruption of the connections to the inductive proximity switches |

Other data

| Note (applications) | safe standstill monitoring |

Notes

| Note (General) | Inductive loads (e.g. contactors, relays, etc.) are to be suppressed by means of a suitable circuit. |

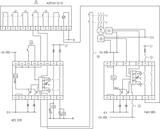

Circuit example

| Note (Wiring diagram) | The wiring diagram is shown with guard doors closed and in de-energised condition. The ISD tables (Intergral System Diagnostics) for analysis of the fault indications and their causes are shown in the appendix. To monitor one guard door at plants with dangerous run-on movements up to PL d and Category 3 Standstill monitoring for unlocking solenoid interlocks The solenoid interlock can be opened, when the fail-safe standstill monitor has detected the end of the run-on movement by means of two inductive proximity switches. When the button (E) is actuated, the coil of the solenoid interlock is energised. For suitable IFL range p-type inductive proximity switches, refer to 'Schmersal Catalogue Automatisierungstechnik'. |