- Monitoring of BNS range magnetic safety sensors

- 2 safety contacts, STOP 0

Ordering data

| Note (Delivery capacity) | Phased-out product |

| Product type description | AES 1266 |

| Article number (order number) | 101170052 |

| EAN (European Article Number) | 4030661297149 |

| eCl@ss number, Version 9.0 | 27-37-18-19 |

| eCl@ss number, Version 11.0 | 27-37-18-19 |

| ETIM number, version 6.0 | EC001449 |

| Available until | 31.12.2021 |

Approval - Standards

| Certificates | BG cULus EAC |

General data

| Standards | IEC/EN 60204-1 IEC 60947-5-3 BG-GS-ET-14 BG-GS-ET-20 EN ISO 13849-1 |

| Climatic stress | EN 60068-2-3 BG-GS-ET-14 |

| Enclosure material | Glass-fibre reinforced thermoplastic, ventilated |

| Material of the contacts, electrical | Ag-Ni 10 and 0.2 µm gold-plated |

| Gross weight | 174 g |

General data - Features

| Stop-Category | 0 |

| Wire breakage detection | Yes |

| Short-circuit recognition | Yes |

| Feedback circuit | Yes |

| Automatic reset function | Yes |

| Start-up test | Yes |

| Reset after disconnection of supply voltage | Yes |

| Earth connection detection | Yes |

| Integral System Diagnostics, status | Yes |

| Number of LEDs | 1 |

| Number of openers | 2 |

| Number of shutters | 2 |

| Number of undelayed semi-conductor outputs with signaling function | 2 |

| Number of safety contacts | 2 |

| Number of signalling outputs | 2 |

Safety appraisal

| Standards | EN ISO 13849-1 IEC 61508 |

Safety appraisal - Relay outputs

| Performance Level, up to | d |

| Control category to EN13849 | 3 |

| PFH-value | 1.00 x 10⁻⁷ /h |

| Notice | for max. 50,000 switching cycles/year and max. 80% contact load |

| Safety Integrity Level (SIL), suitable for applications in | 2 |

| Mission time | 20 Year(s) |

Mechanical data

| Mechanical life, minimum | 20,000,000 Operations |

| Mounting | Snaps onto standard DIN rail to EN 60715 |

Mechanical data - Connection technique

| Terminal Connector | Screw connection rigid or flexible |

| Terminal designations | IEC/EN 60947-1 |

| Cable section, minimum | 0.25 mm² |

| Cable section, maximum | 2.5 mm² |

| Tightening torque of Clips | 0.6 Nm |

Mechanical data - Dimensions

| Width | 22.5 mm |

| Height | 100 mm |

| Depth | 121 mm |

Ambient conditions

| Degree of protection of the enclosure | IP40 |

| Degree of protection of the mounting space | IP54 |

| Degree of protection of clips or terminals | IP20 |

| Ambient temperature, minimum | +0 °C |

| Ambient temperature, maximum | +55 °C |

| Storage and transport temperature, minimum | -25 °C |

| Storage and transport temperature, maximum | +70 °C |

| Resistance to vibrations to EN 60068-2-6 | 10...55 Hz, Amplitude 0.35 mm, ± 15 % |

| Restistance to shock | 30 g / 11 ms |

Ambient conditions - Insulation value

| Rated impulse withstand voltage Uimp | 4 kV |

| Overvoltage category | III |

| Degree of pollution to IEC/EN 60664-1 | 2 |

Electrical data

| Frequency range | 50 Hz 60 Hz |

| Thermal test current | 6 A |

| Rated operating voltage | 24 VAC -15% / +10% 24 VDC -10%/+20%, residual ripple max. 10% |

| Rated AC voltage for controls, 50 Hz, minimum | 20.4 VAC |

| Rated control voltage at AC 50 Hz, maximum | 26.4 VAC |

| Rated AC voltage for controls, 60 Hz, minimum | 20.4 VAC |

| Rated control voltage at AC 60 Hz, maximum | 26.4 VAC |

| Rated AC voltage for controls at DC minimum | 20.4 VDC |

| Rated control voltage at DC, maximum | 28.8 VDC |

| Electrical power consumption | 5 W |

| Contact resistance, maximum | 0.1 Ω |

| Note (Contact resistance) | in new state |

| Drop-out delay in case of power failure, typically | 80 ms |

| Drop-out delay in case of emergency, typically | 20 ms |

| Pull-in delay at automatic start, maximum, typically | 100 ms |

| Pull-in delay at RESET, typically | 20 ms |

Electrical data - Safe relay outputs

| Voltage, Utilisation category AC15 | 230 VAC |

| Current, Utilisation category AC-15 | 6 A |

| Voltage, Utilisation category DC13 | 24 VDC |

| Current, Utilisation category DC13 | 6 A |

| Switching capacity, minimum | 10 VDC |

| Switching capacity, minimum | 10 mA |

| Switching capacity, maximum | 250 VAC |

| Switching capacity, maximum | 8 A |

Electrical data - Digital inputs

| Input signal, HIGH Signal 1 | 10 … 30 VDC |

| Input signal, LOW Signal 0 | 0 … 2 VDC |

| Conduction resistance, maximum | 40 Ω |

Electrical data - Digital Output

| Voltage, Utilisation category DC12 | 24 VDC |

| Current, Utilisation category DC12 | 0.1 A |

Electrical data - Relay outputs (auxiliary contacts)

| Switching capacity, maximum | 24 VDC |

| Switching capacity, maximum | 2 A |

Electrical data - Electromagnetic compatibility (EMC)

| EMC rating | EMC-Directive |

Integral system diagnosis (ISD)

| Note (ISD -Faults) | The following faults are registered by the safety monitoring modules and indicated by ISD. |

| Faults | Failure of the safety relay to pull-in or drop-out Failure of door contacts to open or close Cross-wire or short-circuit monitoring of the switch connections Interruption of the switch connections Fault on the input circuits or the relay control circuits of the safety monitoring module |

Other data

| Note (applications) | Safety sensor Guard system |

Notes

| Note (General) | Inductive loads (e.g. contactors, relays, etc.) are to be suppressed by means of a suitable circuit. |

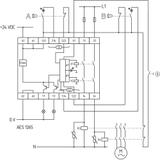

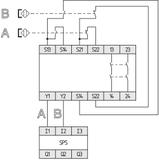

Circuit example

| Note (Wiring diagram) | The wiring diagram is shown with guard doors closed and in de-energised condition. Monitoring 2 guard door(s), each with a magnetic safety sensor of the BNS range The ISD tables (Intergral System Diagnostics) for analysis of the fault indications and their causes are shown in the appendix. Expansion of enable delay time: The enable delay time can be increased from 0.1 s to 1 s by changing the position of a jumper link connection under the cover of the unit. To secure 2 guard doors up to PL d and Category 3 The feedback circuit monitors the position of the contactors K3 and K4. Start push button: A start push button (NO) can optionally be connected into the feedback circuit. With the guard door closed, the enabling paths are then not closed until the start push button has been operated. If only one external relay or contactor is used to switch the load, the system can be classified in Control Category 3 to ISO 13849-1, if exclusion of the fault “Failure of the external contactor” can be substantiated and is documented, e.g. by using a reliable down-rated contactor. A second contactor leads to an increase in the level of security by redundant switching to switch the load off. If neither start button nor feedback circuit are connected, a jumper connection must be mounted between X1 and A1. |