- Reset with trailing edge

- 1 safety contact

- Suitable for signal processing of emergency stop control devices, interlocking equipment, etc

- Installation in Ex-Zone 2

Ordering data

| Product type description | SRB101EXi-1R |

| Article number (order number) | 103037574 |

| EAN (European Article Number) | 4030661542720 |

| eCl@ss number, Version 9.0 | 27-37-18-19 |

| eCl@ss number, Version 11.0 | 27-37-18-19 |

| ETIM number, version 6.0 | EC001449 |

Explosion protection

| Explosion protection: regulations | EN 60079-0 EN 60079-11 EN 60079-15 |

| Explosion protection zones | 1 21 |

| Explosion protection category | 2D 2G |

| Explosion protection designation | D II 3 G Ex nA nC IIC T5 Gc (Installation SRB, in Zone 2) D II (2) G [Ex ib Gb] IIC D II (2) D [Ex ib Db] IIIC |

General data

| Climatic stress | EN 60068-2-78 |

| Enclosure material | Glass-fibre reinforced thermoplastic, ventilated |

| Material of the contacts, electrical | AgSn0. self-cleaning, positive drive |

| Gross weight | 263.8 g |

General data - Features

| Stop-Category | 0 |

| Wire breakage detection | Yes |

| Short-circuit recognition | Yes |

| Automatic reset function | Yes |

| Earth connection detection | Yes |

| Integral System Diagnostics, status | Yes |

| Number of auxiliary contacts | 1 |

| Number of LEDs | 5 |

| Number of openers | 2 |

| Number of safety contacts | 1 |

Safety appraisal

| Standards | EN ISO 13849-1 EN 60947-5-1 IEC 61508 |

Safety appraisal - Relay outputs

| Performance level, stop 0, up to | e |

| Category, Stop 0 | 4 |

| Diagnostic Coverage (DC) Level, Stop 0 | ≥ 99 % |

| PFH-Value Stop 0 | 2.00 x 10⁻⁸ /h |

| Safety Integrity Level (SIL), Stop 0, suitable for applications in | 3 |

| Mission time | 15 Year(s) |

| Common Cause Failure (CCF), minimum | 65 |

Mechanical data

| Mechanical life, minimum | 10,000,000 Operations |

| Mounting | Snaps onto standard DIN rail to EN 60715 |

Mechanical data - Connection technique

| Terminal designations | IEC/EN 60947-1 |

| Cable section, minimum | 0.25 mm² |

| Cable section, maximum | 2.5 mm² |

| Tightening torque of Clips | 0.6 Nm |

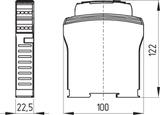

Mechanical data - Dimensions

| Width | 22.5 mm |

| Height | 100 mm |

| Depth | 121 mm |

Ambient conditions

| Degree of protection of the enclosure | IP40 |

| Degree of protection of the mounting space | IP54 |

| Degree of protection of clips or terminals | IP20 |

| Ambient temperature, minimum | -25 °C |

| Ambient temperature, maximum | +60 °C |

| Storage and transport temperature, minimum | -40 °C |

| Storage and transport temperature, maximum | +85 °C |

| Resistance to vibrations to EN 60068-2-6 | 10 ... 55 Hz, Amplitude 0.35 mm |

| Restistance to shock | 30 g / 11 ms |

Ambient conditions - Insulation value

| Rated impulse withstand voltage Uimp | 4 kV |

| Overvoltage category | III |

| Degree of pollution to IEC/EN 60664-1 | 2 |

Electrical data

| Operating Current | 57 mA |

| Rated operating voltage | 24 VDC -15%/+20%, residual ripple max. 10% |

| Rated AC voltage for controls at DC minimum | 20.4 VDC |

| Rated control voltage at DC, maximum | 28.8 VDC |

| Utilisation category AC-15 | 230 VAC |

| Utilisation category AC-15 | 2 A |

| Utilisation category DC-13 | 24 VDC |

| Utilisation category DC-13 | 2 A |

| Electrical power consumption | 3 W |

| Contact resistance, maximum | 0.1 Ω |

| Note (Contact resistance) | in new state |

| Drop-out delay in case of power failure, typically | 20 ms |

| Drop-out delay in case of emergency stop, maximum | 20 ms |

| Pull-in delay at automatic start, maximum, typically | 300 ms |

| Pull-in delay at RESET, typically | 20 ms |

Electrical data - Digital inputs

| Conduction resistance, maximum | 30 Ω |

Electrical data - Electromagnetic compatibility (EMC)

| EMC rating | EMC-Directive |

Other data

| Note (applications) | Safety sensor Guard system Emergency-Stop button Pull-wire emergency stop switches |

Notes

| Note (General) | Inductive loads (e.g. contactors, relays, etc.) are to be suppressed by means of a suitable circuit. |

Circuit example

| Note (Wiring diagram) | The wiring diagram is shown with guard doors closed and in de-energised condition. Monitoring 1 guard door(s), each with a magnetic safety sensor of the BNS range If only one external relay or contactor is used to switch the load, the system can be classified in Control Category 3 to ISO 13849-1, if exclusion of the fault “Failure of the external contactor” can be substantiated and is documented, e.g. by using a reliable down-rated contactor. A second contactor leads to an increase in the level of security by redundant switching to switch the load off. To secure a guard door up to PL e and Category 4 The feedback circuit monitors the position of the contactors KA and KB. Automatic start: The automatic start is programmed by connecting the feedback circuit to the terminals X1/X2. If the feedback circuit is not required, establish a bridge. |